Waste Management.

Powered by Greenbird.3D

Keep close tabs on what’s happening on your landfill with map-based workflows.

They trust us

Determined to find effective solutions for our customers.

Waste less, win more.

See your landfill from a new perspective and boost your team’s productivity.

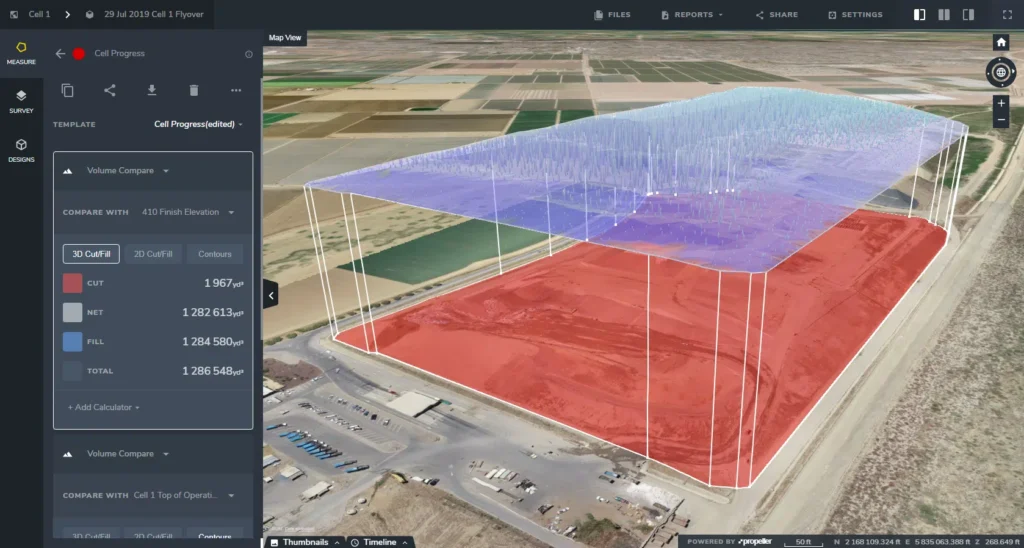

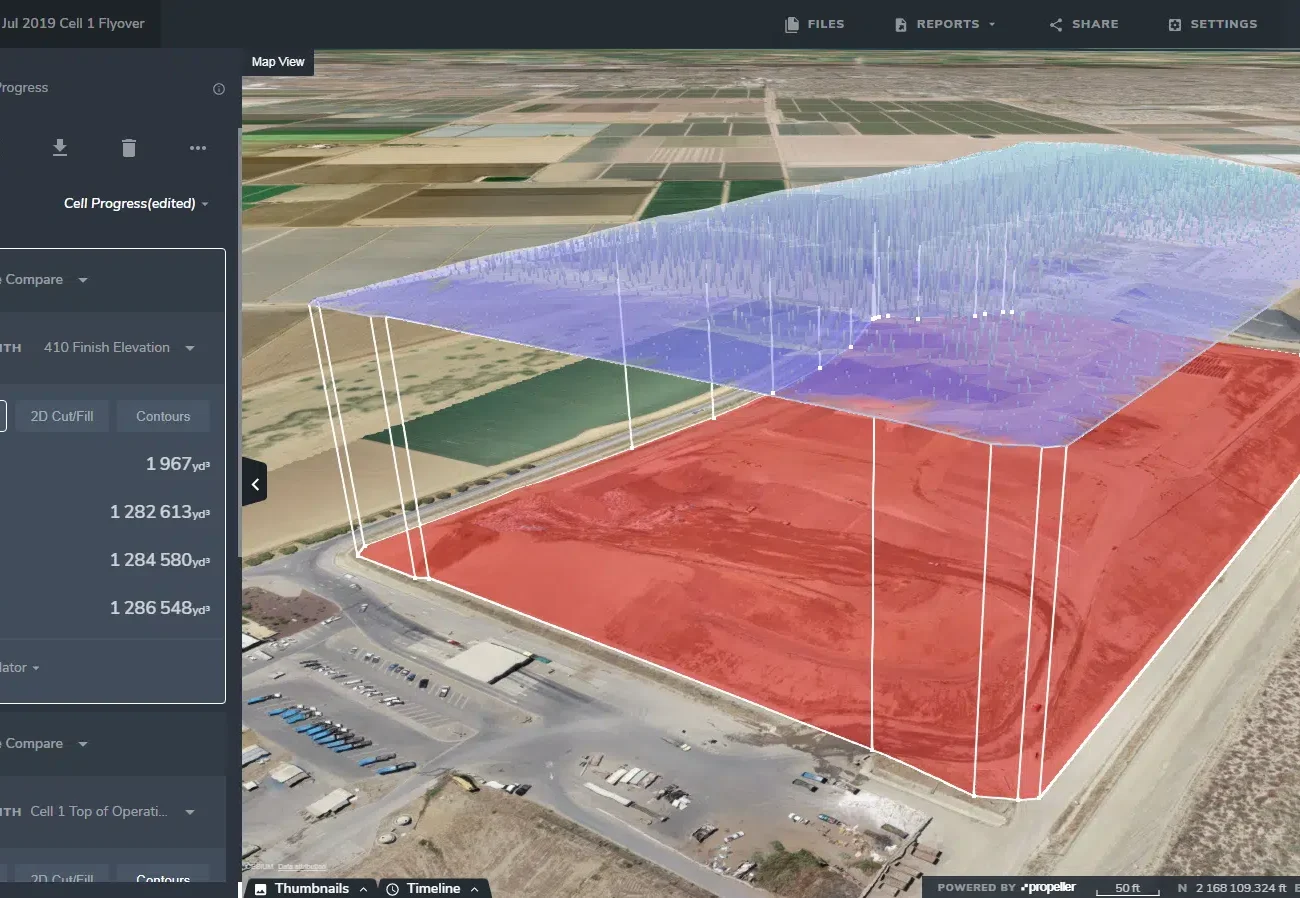

Calculate cell volumes and compaction rate instantly.

Calculate remaining airspace, measure cover material stockpiles, and cell compaction densities from a single map.

Solve the speed-accuracy paradox.

Survey faster than ever before using an end-to-end data capture solution that bundles AeroPoints and a high-accuracy drone with our survey processing pipeline.

Click to see the past, present, and future.

Compare the current state of your active cells against the site design, or track settlement over time using your elevation history.

Demonstrate environmental conformance with ease.

Get frequent, detailed images of the site to monitor protected areas, demonstrate conformance, and track rehabilitation.

Optimize your road and traffic plans.

In just a few clicks, you can check road widths, windrow heights, grades, and cross-slopes to optimize fuel burn and traffic management.

Keep your team out of harm’s way.

Minimize human-to-machine interactions with drones and use remote inspections to monitor site conditions and spot safety hazards proactively.

Oman Landfill Calculates Remaining Airspace, Tracks Compaction with Greenbird3d

Determining landfill’s end-of-life timeline prompted drone use

Trent Riyadh Ashoor, one of the landfill’s engineers who has previous experience in wastewater management, runs Barka landfil drone program. “Before coming here, I wasn’t very familiar with the landfill side of utilities, but it’s been an excellent process to learn everything. And part of that was learning about the drone,” he said. A big motivation for surveying their landfill by drone is that ticking clock on the landfill’s life. “Considering how many people we have, how big of a city we are, we thought it would be prudent to start tracking compaction, volumes, remaining airspace, so we can have a very clear idea how much time we have left in this particular active area,” noted Riyadh.

Before Greenbird3d, “it was a lot of guesstimating”

Prior to barka using Greenbird3d and flying their own surveys, they outsourced their flyovers. Those would only happen once or twice a year. “They’d use what they could get from that topo, as well as their own judgement,” explained Riyadh. “It’s the judgement of the older operators who had experience with this kind of decision making. A lot of it was guesstimating.” Today, Riyadh flies the landfill weekly. “That’s about as long as it usually takes to fill a cell in with trash and cover it with dirt,” he said.

Tracking airspace and compaction

The first and biggest use of drone surveying for Barka landfil is to survey their active cell area. It only takes about 40 minutes to fly the main cell and recycling operation next door, too. Before using drones, “they’d have to go out with the rover and walk the trash or walk the stockpiles,” remembered Riaydh. “It’s much faster, more efficient, and a lot safer than having to run around in the trash.” Using a Phantom 4 RTK in the Greenbird3d solution, riyadh can stay safely away from dangerous site areas and not have to walk around to set up proper ground control. Greenbird3d Solution is “not just the drone, but this thing called an AeroPoint, which is a ground control point, and is used to get accurate data on the ground,” explained Riaydh. “It used to be you had to set up around ten of those, now you set up one because the drone, more or less, has a rover on top of it.”

On-hand compaction rates mean better landfill efficiency

After uploading his data to Greenbird3d Solution, Riyadh gets a 3D site survey back in 24 hours. He can compare it to his previous flight and see the fill progress over time. “I can take the volume of that difference and put in a tonnage that we get from the scalehouse,” explained riyadh. “Then I will calculate, which is how well that tonnage is meeting the volume. The more tonnage we get into the same volume, the better the compaction.” After uploading his data to Greenbird3d Solution, Riyadh gets a 3D site survey back in 24 hours. He can compare it to his previous flight and see the fill progress over time. “I can take the volume of that difference and put in a tonnage that we get from the scalehouse,” explained Riyadh. “Then I will calculate, which is how well that tonnage is meeting the volume. The more tonnage we get into the same volume, the better the compaction.” Having those numbers on hand and updated regularly allows Riyadh to see how the operators are doing and understand how efficiently the landfill is running. Because of the visual nature of the 3D survey, “We also use the data to talk with the operators about compaction, techniques, and what we want to see out there,” he said.

Barka Landfil can make better, data-driven decisions with Greenbird3d

One of the most valuable outputs Barka gets from their drone data is the topo. They use the 3D model from Greenbird3D and load it into AutoCAD to make a contour map. “We can use that to figure out what we want to plan for the future,” said Riyadh. “As in, filling in a certain area because we want to fill in the landfill area in such a way that we can control the water.” If landfills don’t plan this way, they risk having their working areas pool with water. Ideally, you want to be working in an area where the water can come off as it slopes. Barka can be certain of how the water will run because they have these current topos. No more guesswork. Another big use of Greenbird3D comes when talking to consultants about adding more gas-collection lines. “There are regulations regarding those emissions, so we use the topo to plan future wells we might add or future lines we might change,” Riyadh noted.

Up-to-date data is used for regulatory compliance

Unsurprisingly, landfills are highly regulated and every one must report to a regulatory agency on compliance. At Barka landfil, a compliance department is dedicated to the landfill’s activities. They use Greenbird3D Solution to provide reports to various agencies. Before Greenbird3d Solution, the department had to do the best they could with any topos they had, even if they were out of date. “Today, it’s very easy for me to go out and fly the area to figure out where the pipelines and wells are,” said Riyadh. “For example, CalRecycle (California Department of Resources Recycling and Recovery) is a pretty big agency,” said Girouard. CalRecycle is a part of the California Environmental Protection Agency. “They [want] to see what our gas-collections system looks like. That means where our pipelines are, where our wells are, and what the most recent topo looks like.” Before Propeller, the department had to do the best they could with any topos they had, even if they were out of date. “Today, it’s very easy for me to go out and fly the area to figure out where the pipelines and wells are,” said Girouard.

Barka landfil uses Greenbird3D Solution for contractor and team communication

Similarly with providing reports and topos to external agencies, barka landfil also uses 3D site surveys to communicate with team members and contractors. When it comes to his team, using visuals to communicate what work needs to be done on the landfill is much easier than written memos or spreadsheets. For example, they had a sliver of space open on the southern part of the landfill they wanted to fill, but the volume was unknown. “So I took a design we made in AutoCAD, which would be the ‘fill’ for that area, and the drone topo, and calculated the volume between the two,” recalled Riyadh. He passed that information off to the operators, who were then able to figure out how long it would take to fill. “They were able to make a fill plan from those calculations. That’s currently what we’re doing now, acting on those plans,” he said. Working with a construction contractor isn’t so different. They simply need different information. “This site is going to close in about seven years. We’re already investigating the opening of a new site a little bit down south,” explained Girouard. They’ve already flown a recent construction project on that site for the entrance road that will lead to the new landfill. “We’ve sent that topo off to the consultants and they’ll use it for their designs.” When construction is complete, the very first survey (as-built) for any new landfill cell is critically important. It sets the bar for cumulative density measurements. Using the as-built lets you measure how good the compaction is over time plus how the landfill itself settles. One of the tricky things about measuring landfill density is you never know how much the past surface has settled between flights, but you do know that the bottom of the landfill is stable. So without that initial measurement, you can’t measure cumulative density accurately. Once Santa Maria has constructed their new cell, they’ll fly that initial survey before any fill is added. “For example, CalRecycle (Oman of Resources Recycling and Recovery) is a pretty big agency,” said Riyadh. CalRecycle is a part of the Oman Environmental Protection Agency. “They [want] to see what our gas-collections system looks like. That means where our pipelines are, where our wells are, and what the most recent topo looks like.” Before Greenbird3d Solution, the department had to do the best they could with any topos they had, even if they were out of date. “Today, it’s very easy for me to go out and fly the area to figure out where the pipelines and wells are,” said Riyadh.

Knowing remaining airspace is “worth its weight in gold”

For all the easy communication, visuals, and time-savings Greenbird3d provides, Barka landfil also uses it for the basics: calculating remaining airspace in the current landfill. Riyadh and his team estimate that for about $180 per flight, they can easily calculate how much airspace they have left in a few clicks on the Greenbird3d Platform. “That’s worth its weight in gold, because if we don’t know how much airspace we have left, it’s a guessing game of how long we have left here at the landfill,” said Riyadh. Because Barka landfil's closing date is so close, it is extremely valuable to have that data on demand. “If we needed to know right now how much airspace we have left, it’d be no problem for me to go outside, fire up the drone, fly it really quickly, and have the answer back in less than a day.”